Dust Control with Misting and Fogging Systems

Effective dust control over large open areas and inside a building is vital to any Australian business. There are many processes that generate particulate matter resulting with fugitive dust and airborne dust being dispersed across many areas of the work site.

CoolMist System Australia's customised misting systems provide an affordable dust suppression solution in areas where extraction is not possible or affordable.

Since 2005, CoolMist Systems Australia has assisted numerous clients with their tailored dust control solutions.

Our industrial dust suppression misting systems are used throughout Australia in mining operations, waste transfer facilities, recycling facilities, bulk processing facilities, excavation or construction sites, building demolition, steel and slag facilities.

Dust control with fogging systems is a methodology that uses fine water mist to prevent dust lift-off and suppress the amount of dust in the air. CoolMist® dust suppression systems are cost effective and efficient, have low operating costs and can be easily fitted to any size building or work process.

Also in our range are our powerful AJet® Mist Cannons. These dust-fighting machines cover wide areas and are available for fixed or mobile installation.

CoolMist Systems Australia's dust control methods improve the quality of the air in working areas and is beneficial for workers, machinery and the environment.

Why CoolMist® systems are better

Let our expert team help you solve your dust suppression problem with our professional advice, design and installation service.

Dust Suppression FAQs

What are the benefits of the CoolMist® Dust Suppression System?

Improve Health & Safety

Reduce skin and eye irritation

Increase workplace visibility

Lower the risk of respiratory illness by reducing dust levels

Clean, cool and condition the air providing an improved work environment

Lower the risk of dust explosion and fire

Environmentally Sustainable

Avoid dust-off by controlling dust particles at the source and on site

Lower contamination in nearby ecosystems

Lessen the nuisance and impact on neighbouring properties

Low volume water mist is more efficient and avoids oversaturation, run-off and other residual problems common with traditional water spray systems

Surrounding areas remain dry with water efficient dust suppression

Meet Australian environmental regulations

Lower Operational Costs

Power consumed is only a fraction of the cost when compared to conventional systems

Reduce clean-up and dust disposal costs

Lower litigation risk and ease regulatory body concerns such as the potential threat of shutdown and unnecessary fines

Lower maintenance and repair costs through dust control, with less wear and tear on machinery

No expensive consumable chemicals

Productivity

Increase equipment performance and reliability

Prevent unscheduled production breakdowns due to dust accumulation and ingression on equipment and machinery

Processed material quality is not compromised by avoiding chemical additives and over-saturation

Boost morale, and provide a cooler and more comfortable workplace for employees on-site

Increase performance and reliability

Prevent unscheduled shutdowns from equipment failure due to dust and clogging

Tailored systems

Target specific dust points and prevent dust emission from the source

High concentration of micro-fine fog droplets provides efficient dust suppression

Avoid water pooling by using atomised mist. Plant, machinery, floor area and process material remain dry

Personnel can work in the fog without becoming wet

Proven capability to suppress aero-dispersed dust from 50% - 92%

Catered to large, small, or whole of site solutions

What is industrial dust?

Dust consists of tiny particles of dry, solid matter. Industrial dust is a by-product of activities such as earthworks, excavation, blasting, transportation, product processing, manufacturing and waste and recycling processes. Dry climatic conditions and wind can intensify dust generation.

Dust has a significant health and environmental impact associated within many areas including mining, construction, demolition, manufacturing, and agriculture industries.

Many operators are challenged daily as dust particles pose serious health issues, increased maintenance cost and down times, loss of material, product quality and reduced productivity and regulatory compliance.

Why is dust control important to industrial operations?

Without proper dust control, your workers are exposed to harmful dust, particulates, and contaminants in the air. Airborne dust particles cause breathing difficulties, skin and eye irritation, and serious respiratory diseases. Prolonged exposure to these dust particles can significantly affect the health and well-being of your workforce.

Dust can damage and interfere with the functionality of equipment like conveyors and their components, plant and equipment, motors, and machinery. Constant exposure to dust can result in frequent and unscheduled shutdowns and increasing clean-up costs.

When dust escapes beyond site boundaries, it can have a negative impact on near-by properties and eco-systems.

By having proper dust control measures onsite, you can improve operations with continuous productivity, a safer, healthier, and cleaner workplace for employees and meet OH&S and environmental obligations.

How does CoolMist Systems Australia manage dust?

CoolMist Systems Australia supplies dust suppression systems for indoor and outdoor applications. Finding the right dust suppression solution for your workplace may be as simple as a fogging system installed at the dust source or you may require a larger system installed to run a number of zones.

Static line misting systems use high pressure (70bar, 1,000 psi) pumps to atomise water into microscopic droplets to limit the dispersion of fine dust particles. A network of strategically placed misting nozzles emit the fine spray of micron-sized water droplets that absorb the dust particles in the air. The increased weight of the dust particles causes them to fall back down to the ground or to the process material and remain there, leaving the air dust-free. Utilising this method of dust suppression can greatly inhibit dust from circulating throughout the entire facility.

Additionally, mist fans fixed to walls or 360 mist fans suspended from the ceiling can be considered as effective dust suppression tools.

Mist cannons - also recognised as fog cannons, dust cannons, fog makers, spray cannons - are used for dust suppression in many work processes in quarry operations, mine sites, demolition and construction sites.

AJet® Mist Cannons propel atomised mist with a high velocity fan over large areas. CoolMist® mist cannons throw fog from 15 to 150 metres, which makes them a powerful and effective solution for dust control. Water flow rates can be adjusted to regulate the volume of water discharged from the mist cannon to control both surface dust and airborne dust without saturation problems. The cannons can be setup in a fixed or mobile position depending on your specific needs.

A professionally designed and installed dust suppression misting system can remove dust particles from 0.1 to 1000 microns reducing PM10 dust levels and assist compliance with EPA dust control standards. Our team will assess the site and dust intensity, matching water droplet size to corresponding dust particle size. Based on your requirements we will tailor a dust control system designed to work effectively and efficiently.

Why is water droplet size a key factor for effective dust suppression?

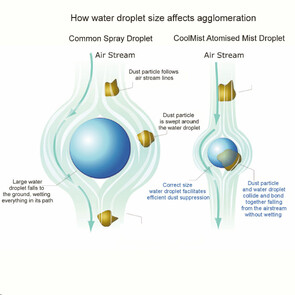

To maximise the potential of dust capture by water dust suppression systems, the water droplets need to be similar in size to that of the dust particles. Water droplets that are too large deflect the dust particle away leaving the dust air borne. The mist density (fog cloud) also needs to be greater than the concentrations of dust in the air so that all the dust can be captured.

Our misting systems and mist cannons operate on the principle of binding dust using tiny water droplets similar in size to the dust particles. CoolMist® misting systems and mist cannons effectively break down PM10 and smaller suspended dust particles by using water droplets similar in size to the dust particles.

Tiny, atomised water droplets, 10 microns, form a dense fog and trap the dust particles increasing their weight which causes them to fall from the air. Particles from 0.1 to 1000 microns have little chance to escape and are quickly arrested, removing dust from the air.

The low volume of water emitted from our systems avoids residual problems such as pooling or oversaturation and achieves dust suppression with maximum efficiency at sustainable water usage rates.

Schedule a consultation with us now

We love working with businesses to solve their cooling, humidification and dust suppressions problems. Contact us about organising a consultation.